Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

The Flux 125 Welder lets you wire weld without dealing with gas tanks or regulators.

A reliable arc welder that works just as well in a professional shop as it does in your garage.

Fix dings and dents without drilling holes—this stud welder gets the job done right.

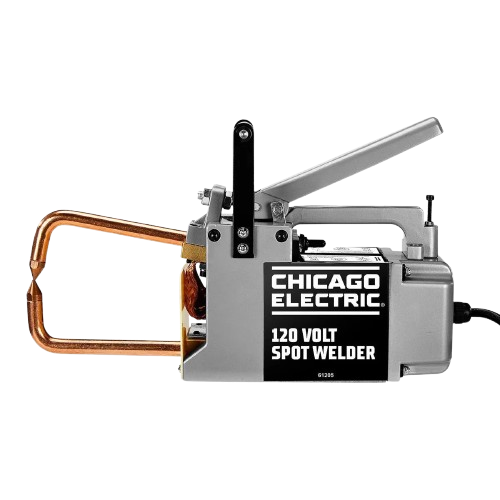

This portable spot welder works with the same 120V power you already have in your home or shop.

A straightforward MIG flux wire welder that gets the job done without the fuss.

A leather apron, leather gloves, and rod holder all bundled together at a reduced price.

Get the latest welding tips, project ideas, and product announcements delivered straight to the inbox.

Chicago Electric Welder started in a South Side garage in 1978, when a third-generation ironworker got tired of equipment that couldn’t keep up with Chicago winters and 12-hour shifts. We make welders that work as hard as you do — because we’ve been there, torch in hand, trying to get the job done when it’s 10 below and the deadline was yesterday. Our gear isn’t pretty, but neither is real work.

Every welder we build comes from the same place: frustration with tools that promise everything and deliver headaches. We’ve spent decades listening to welders, fabricators, and weekend warriors tell us what breaks, what burns out, and what drives them crazy. Then we go back to our shop and fix it. No focus groups, no corporate consultants — just people who understand that when you’re under a car or sixty feet up on a beam, you need equipment that won’t let you down.

We’re still in Chicago, still family-owned, and still answering our own phones. When you buy from us, you’re not getting a box from a warehouse — you’re getting equipment tested in the same brutal conditions you face. Our warranty isn’t full of fine print because we build things to last, not to break right after the coverage expires. If you’ve got a problem, call us. If you need advice, call us. Hell, if you just want to complain about the Bears while you’re on hold, we get it.

Chicago Electric welders prove you don’t need to spend thousands to get professional welding capability. Whether you’re fixing farm equipment, building custom projects, or running a small fabrication business, these machines deliver the power and reliability that matter—without the premium price tag that doesn’t.

“Look, it’s a Harbor Freight welder – you know what you’re getting. But I’ve built two car trailers and countless shop projects with my Chicago Electric. Just keep it clean and don’t push it past its limits.”

Mike D.

“Bought the Chicago Electric stick welder for farm equipment repairs. It’s not a Miller or Lincoln, but for fixing gates and patching implements, it gets the job done. Three years in and still running strong.”

Roberto C.

“As a beginner, I was intimidated by welding equipment prices. The Chicago Electric MIG helped me start my metal art business without going into debt. Sure, I’ll upgrade eventually, but this got me earning first.”

Ashley T.

Most units require a dedicated 220V circuit with appropriate amperage based on the model specifications. A 30-amp breaker typically suffices for smaller units, while larger models may need 40-50 amp circuits. Always consult the manual for specific electrical requirements and have a qualified electrician verify the installation meets local codes.

Material thickness capacity varies by model and amperage settings. Entry-level units typically handle steel up to 1/4 inch thick, while higher-powered models can weld 3/8 inch or thicker materials. Aluminum and stainless steel may require different settings and potentially different wire types. Multiple passes can extend thickness capabilities for some applications.

Standard flux-core wire works well for general steel fabrication without requiring shielding gas. For cleaner welds and reduced spatter, solid wire with appropriate shielding gas (typically 75% argon/25% CO2 mix) provides better results. Wire diameter selection depends on material thickness – 0.030″ for thinner materials and 0.035″ for thicker stock.

Thermal protection activates when internal components exceed safe operating temperatures. This commonly occurs from exceeding the duty cycle – running too long without adequate cooling periods. Operating at maximum amperage settings, poor ventilation, or blocked cooling vents can trigger protection sooner. Allow 15-30 minutes for cooling when this occurs.

Regular maintenance includes cleaning spatter from the contact tip and nozzle, checking wire feed tension, and inspecting the ground clamp connection. Monthly tasks involve blowing compressed air through vents to remove dust and checking all electrical connections for tightness. Replace contact tips when the hole becomes enlarged or oval-shaped.

Inconsistent welds often stem from poor ground connections, incorrect wire speed/voltage combinations, or contaminated base metal. Clean all surfaces thoroughly before welding, ensure solid electrical connections, and maintain consistent travel speed and angle. Practice on scrap material to dial in settings before working on final projects.